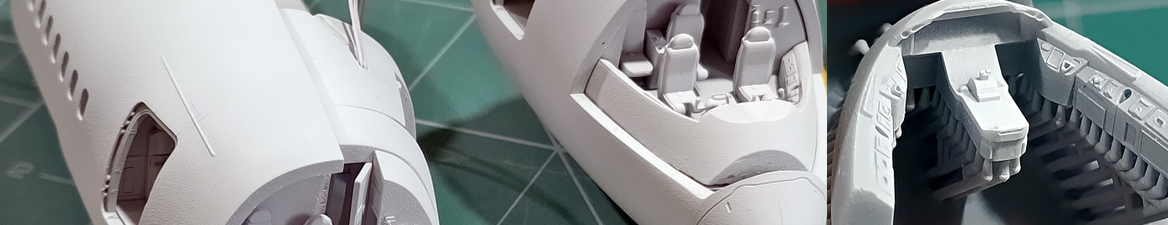

B787 first fuselage test

Hello everyone, Today I am sharing an update that may seem small, but that actually has taken me a lot of time and energies to get done. I did a test on the fuselage assembly, a very quick test which reminded me that modeling is not a quick thing, you need to take your time and dedication, and the reason I feel this way is because it has been so long since I worked on a model… A couple of very important things I need to mention:For several reasons I won’t be able to provide the fuselage in sections, but …