Hello all,

In my previous entry, at the end, I was writing that if everything went well with the B787-9 cargo hold I would be giving an update this weekend.

So I can share with you the work with this cargo hold. It is by no means the same one I tested last week.

After the first casting, I just wasn’t happy with the result I saw some misalignment and things that I really felt were not up to the standards and that I could do better, it was a moment to take an important decision.

The decision; start all over again. I’ve been working hard this week on a new shell, this time I focused on making this in a way I initially thought about, with a shell placed inside the fuselage without needing of cutting nothing but the cargo doors.

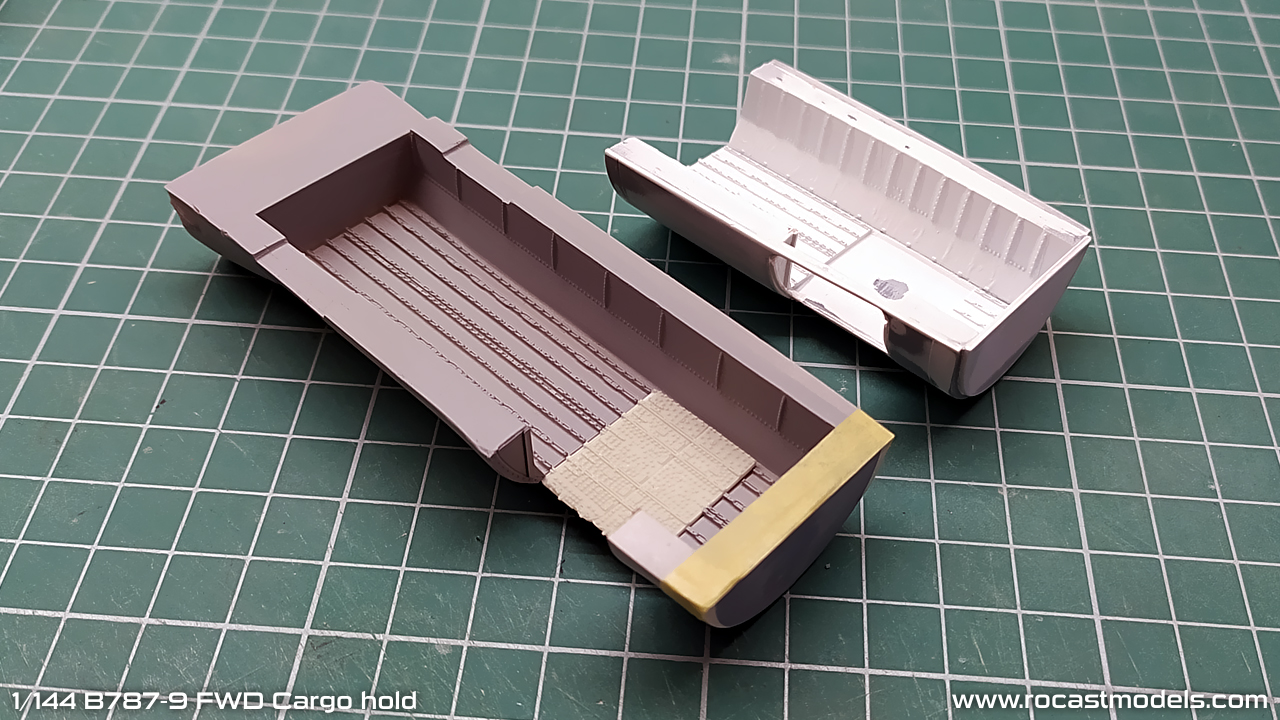

From the image above, you can see the new cargo hold shell (left) and the previous one (right). Not only I made it fit better, but was also able to make it longer which is something that I could not do with the method I used for that cargo hold.

Still, there are limitations, it will only have capacity for 16 LD3 containers since up front I could not extend the hold due the forward galley/cockpit, and at the back (towards the center of the aircraft) I preferred to leave a wide portion so that the fitting on the inside could be more precise.

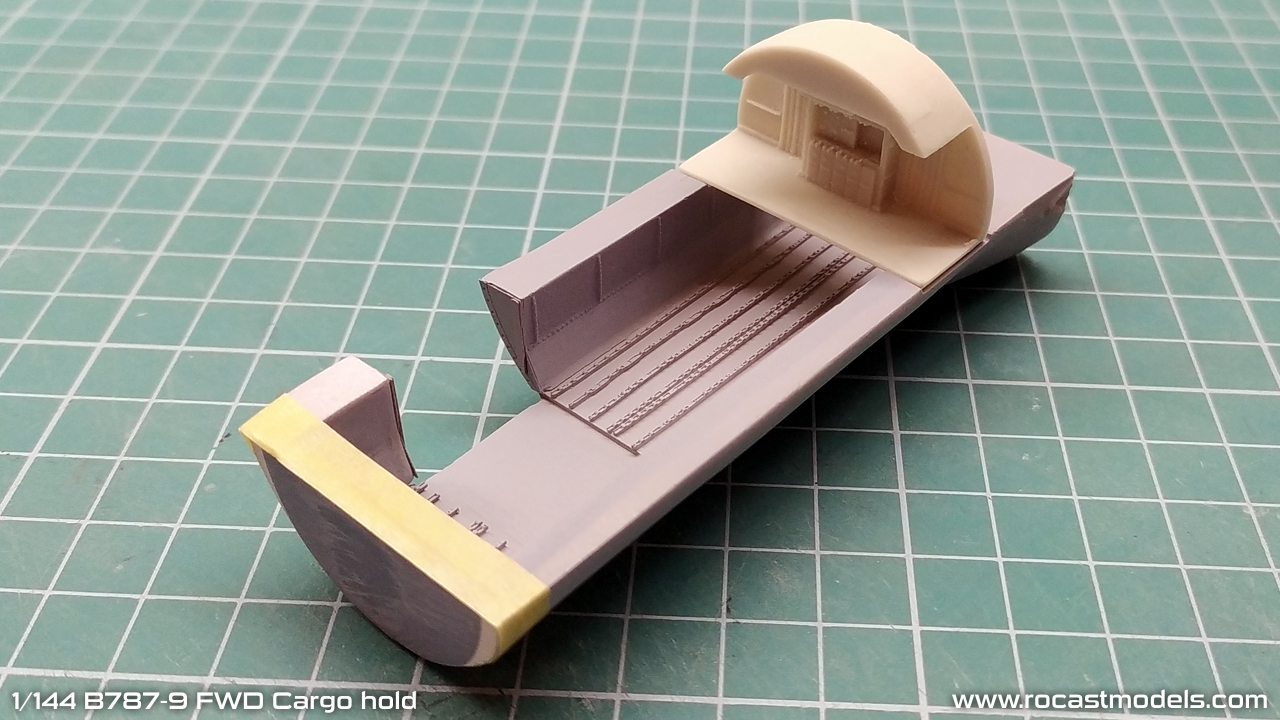

Upon building this new shell I had to think; what about the middle galley? If you recall, the center galley that I made was an overall round disk, the reason for that was to aid on the positioning of the galley itself, so that the space would be equal on both left and right doors.

I did not want, by all means, to sacrifice the middle galley, so a strategy was done which consists in cutting half the disk, leaving 1 mm of floor thickness, and fitting the galley right on top of the dedicated space of the cargo hold.

The lower portion of the middle galley is no longer needed, because it is the cargo hold structure, the one in charge to keep the galley leveled and at equal distances from the doors.

Of course, the open areas you can see on the photo (in front, and behind the middle galley) will be covered by the ceiling. Now, a third portion of the ceiling will also be included, in case you are not using a middle galley, thus closing the area completely.

For my project (which I will be sharing here upon start), I will be using micro leds, which I think will bring the work done inside to life.

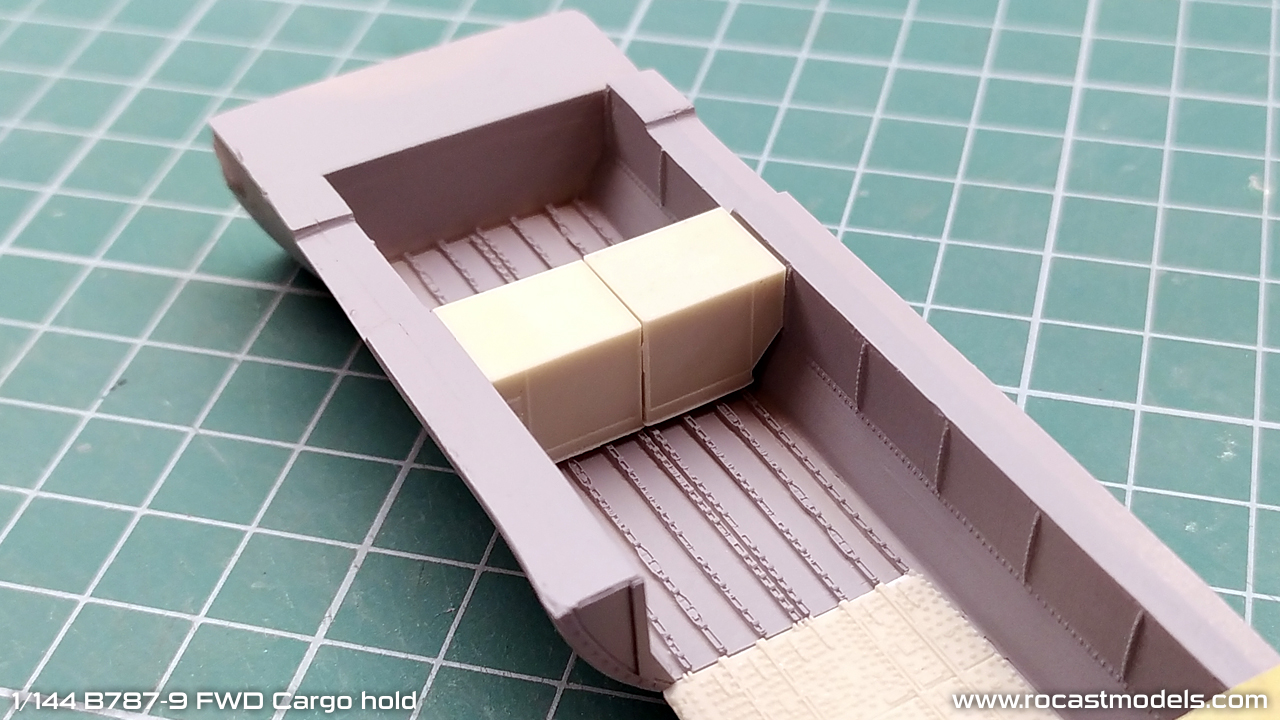

The precision to do this had to be chirurgical, everything fits tight, and although I did not do this on the LD3 containers above, maybe sanding down the container straps would help give some 0,3mm room. This can give you an idea on how much had to be taken into consideration to fit together right.

Note that I made the dividers in such a way so that it can be easier to place the containers and decals for each pallet hub, sta etc.

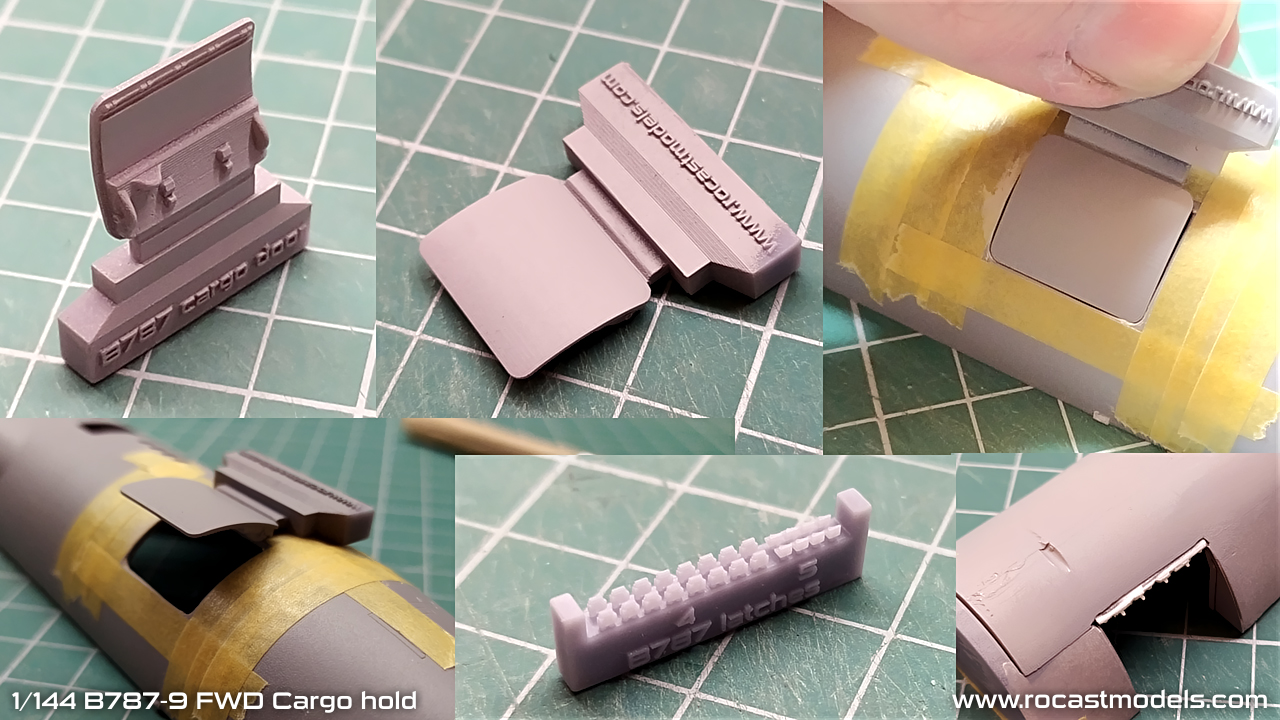

The cargo door was something very interesting for me personally, because due the thickness of the plastic, the containers (made to the equivalent size in 1/144) were a bit too tight to get in, so I had to sand down 1,5mm above the door hole to offset this issue.

The last version of the door shown here, fits very nicely to the hole, I did not have to oversize the original Zvezda door. Regarding the cutting of the door, I have recorded the method I did it with and also took photos that will be a part of the instructions.

Note the latches at the bottom center of the photo, there are plenty included in the set, only 5 (if memory serves me right) need to be used, then other four different types for the lateral walls are also included.

At the bottom right corner you can see another issue that had to be solved; the rollers are actually hanging outside the floor area, between the door gap and the floor level, so by readjusting the positioning of the platform, this was possible, then the latches will be glued below, right on top of the plastic thickness, which is on top of the cut done for the door.

There are still other parts that I wasn’t able to share yet, which are the hinges and door latch. I will be sharing these once I can show a fully 100% completed cargo hold (painted and decaled).

The fitting is very precise with the original molds, this was what I was afraid of and the main reason why I chose the other way on my failed attempt, if the cargo hold was not properly glued at one side of the fuselage, it wouldn’t fit the other one or it would not be leveled.

So with this new method, gluing it by using the references of the mold centerline and joining points, it is very easy to leave the cargo hold perfectly fixed at one side, which translates with a perfect union upon putting the other side.

Despite the failed attempt which took me months of work, a lot was saved such as the platform and the rails (which already took me weeks). The sidewalls were made new, to accommodate the new shell and length.

It took me a week to make this new shell, and as I am finishing this entry, I will be starting with the AFT cargo hold today.

This new method gives me a lot of fresh air for the B747-8F/-400F project for which a similar method will be used, only that in this particular case, the whole main deck will be represented.

This change of plans made me delay the B787-9 cargo holds till the end of the month, not only I need to take into consideration the extra week (if all goes well) for the aft cargo hold, but also time to make the initial units, instructions and decals.

From here I apologize for this delay, it may be that some of you were looking to make a project with them on Christmas, like me, but I think there will be time to have this done and available weeks before Christmas.

I will be writing another entry soon to confirm the release date of the catering truck which will be simultaneously released with the tow tractors: Schopf F59, F110 and F210 as well as the two types of towbars.

Initially, those items would have been released at the end of the month, but they are actually much more advanced (in production phase) than the cargo holdsso I decided to switch dates between them.

That is all for now, I think that the step back with the B787-9 cargo holds was a good move to do, for the life of me I could never release something I am not fully pleased with, so hopefully these new cargo holds will have a much better finish and be of your liking.

Till the next entry, take good care of yourselves.

Best wishes,

Guillem