Hello everyone,

As the 787 project is moving forward, I wanted to give some more updates.

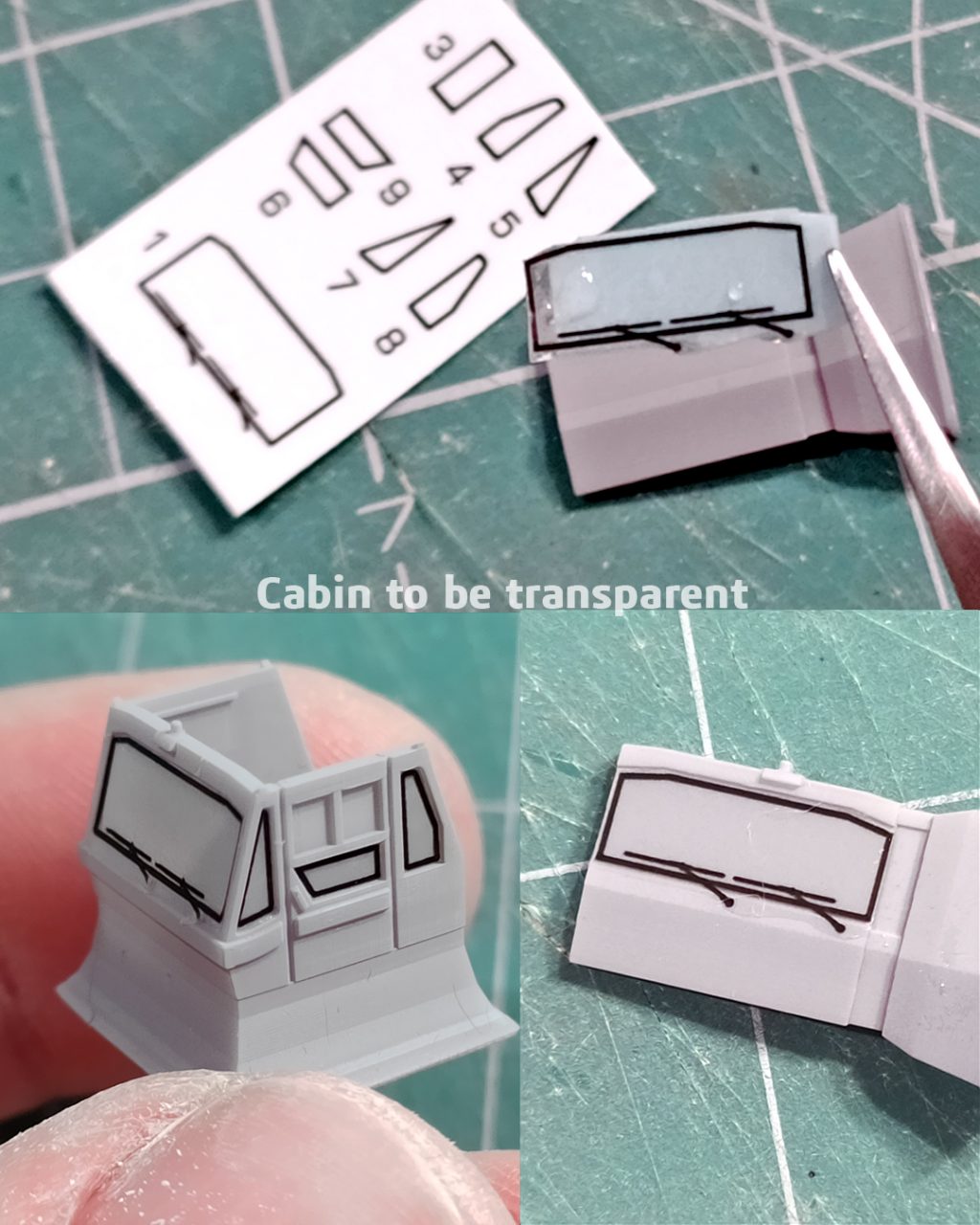

I can finally confirm 100% that the transparent windshields are a reality despite having been able to make one before, when you work with new materials, you need to do further tests to confirm an ensure a manufacturing process.

As you can see, I am working on a B787-8 “Primed” version that will be used as preview example which already has the Revell wings attached to my fuselage. I am also working on the 787-9 version which has the fuselage extensions added.

A release of this kind with several parts joined together, one needs to take some time and actually try and use what’s being done.

The -9 version will be a finished example model this time instead of a “primed” finish for the -8.

Video recordings are being done as I progress with it in which I am adding some tips that will complement visually the already included instructions. I will be publishing the first video as I do more progress with the fuselage.

I am also preparing the so many doors needed for this manufacturing process, some may think the hole for the window is too deep, but there is a reason for it so that I can make that area transparent. With the transparent resin taking days to dry, more master parts are needed for the cast.

What is there left to do?

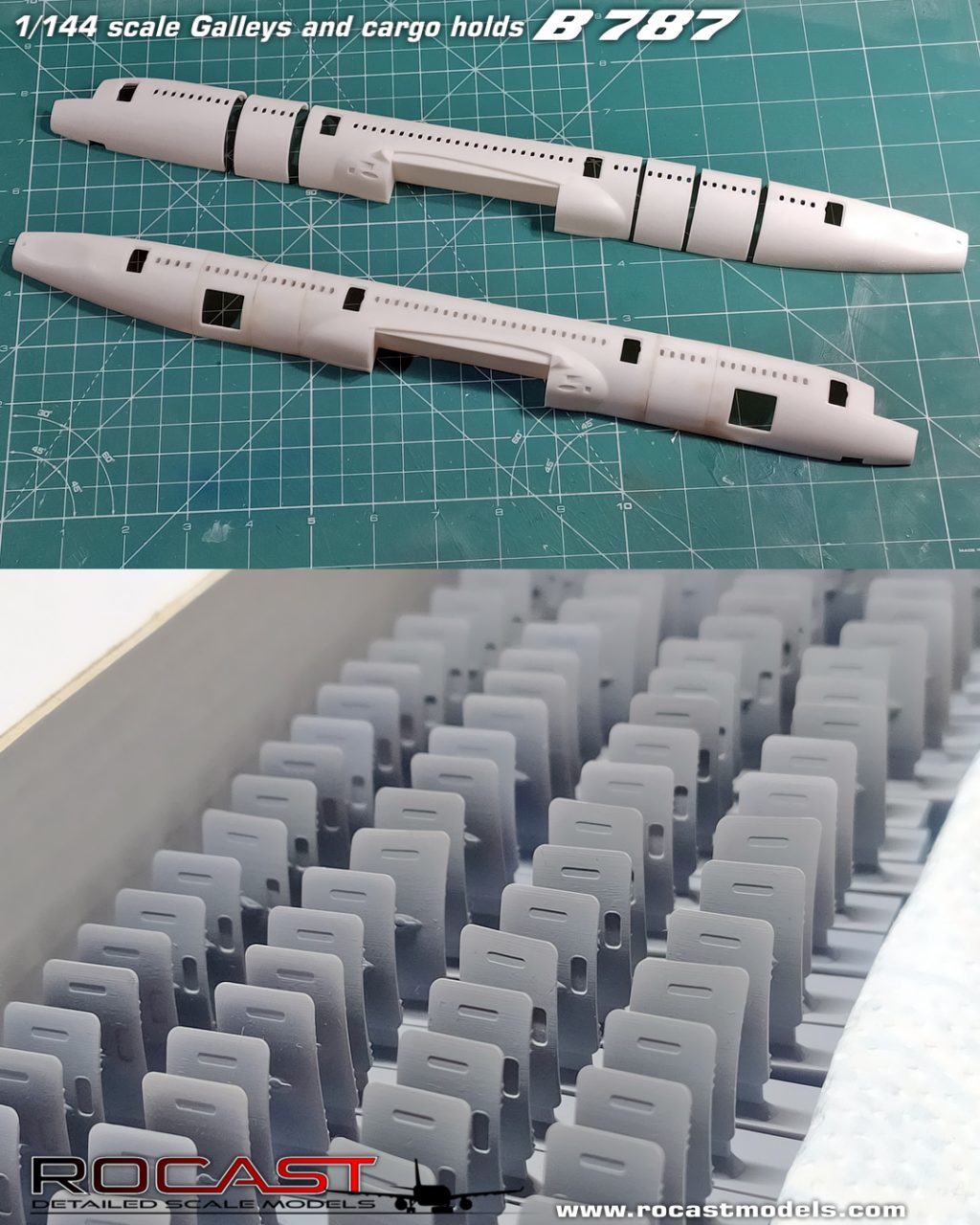

Galley parts are all done for the initial stock of 12 units, both for the full set (with selectable options) and the stand alone versions of the cockpit/fwd galley and aft galley.

I am still working (and reworking) the molds for the cargo holds, nose cone and tail cone, which together with the fuselage sections are the remaining parts to complete the first batch of 12 units.

I wish I could go faster, however, resin needs time to dry when you work with 1,5mm thick parts, the process cannot be altered.

That is one side of my current work, one the other hand I have started my revision of all the GSE models.

I am currently working on what I call a new generation of GSE vehicles.

It has been quite some time since I first started working on these models, my early 3D printing days were difficult starting with zero experience, but as time and technology advances, I can make certain parts that I couldn’t make before.

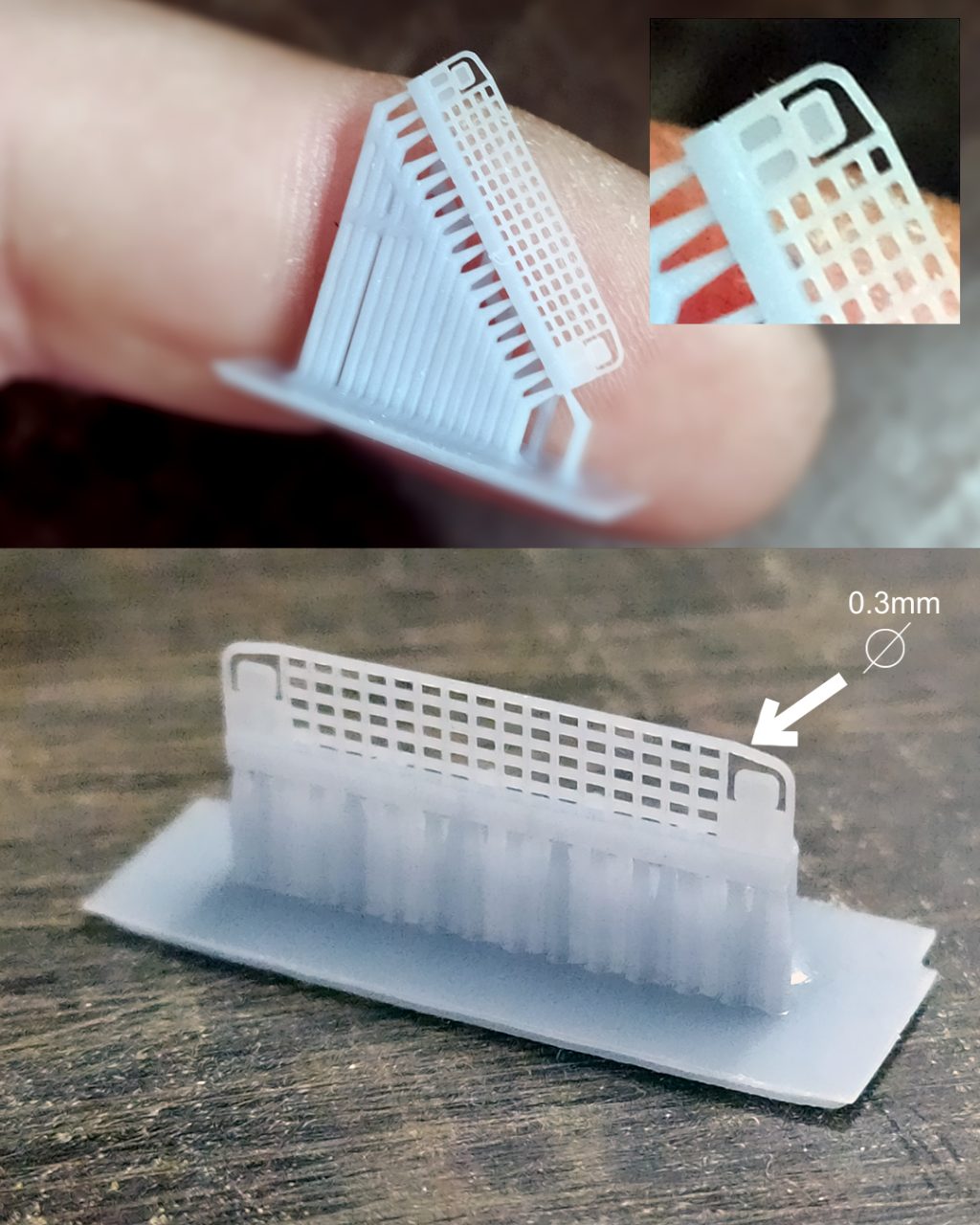

An example that I am sharing here today is the front grid for the AST-1 pushback. It was made with photo etch in the past, but nowadays I can 3D print it with more volume and detail than what a flat photo etched part does. This will also lower the costs and times of production albeit having a more realistic finish.

Improvements on the various models are planned such as transparent cabins accompanied by a masking set for the painting process, masks to paint the wheels will also be included in the sheet.

Models went from photo etched wipers, to vinyl wipers to now decal wipers. To me they look more realistic and subtle, plus decal for the cabin frames are also in the plans for the various trucks. This is currently being tested, while I can also adjust the color of the wipers, somewhere a dark grey may be a better option.

All in all, with time, experience and support from you, I am able to make things better and I am enormously grateful for that. This means that curved cabins are no longer an issue, thus being able to make the pushback trucks that can be seen at Schiphol, or also being able to make the bus Cobus 3000 in clear/tinted windows which is a project I also want to do this year.

It has been the same for the figures, from still clothing to natural wrinkles and folds.

Everything evolves and I know the GSE has the potential for improvement, and that is what I am currently doing before I can put new stock at the shop.

The transfer of most of the GSE models to the current software will take a bit of time, but it will be worth it. Not only working on those improvements, but also making better instructions along the way, with better graphics and design.

It is frustrating in a way not having stock at the moment, but once I finish this process, all the current GSE and some new items will be available.

Also, this process is important towards the 3D printing, where I am “standardizing” files and models to be printed in current and next generation of printers.

This is also going to help me go through the different scales, so naturally models will also be carried over the 1/200 and 1/72 scale.

That is all for now, I will provide another update as soon as I have more content.

Take good care everyone.

Best wishes,

Guillem