Hello everyone,

First entry of September after the summer holidays, hopefully everybody is doing alright, now that we are leaving behind these hot days of summer, it is time to continue working hard.

I would like to comment on the current projects, future ones and minor changes within the online shop.

I would like to start with the 1/200 GSE models:

The units of the 1/200 AST-1 pushback have been out of stock for a long time now, so new units are going to be produced alongside the 1/200 Belt loader which is finally finished.

During these days I have been adjusting several aspects of the figures, since these were the first 1/200 figures that I made, some adjustments on the steering wheel were needed:

This model is quite small, I do not think that I can make smaller figures, but the 1/200 scale would be my limit.

Here is a comparison photo with the 1/144 Belt loader:

Due the considerable small size of parts, as usual some will be included as spares in the set, other details such as the towing hooks and the emergency light mast will be made out of wire, which will also be included. The set is very similar to the 1/144 one, meaning that it will include decals, photo etch, 5 pieces of luggage and the same choice for the driver figures.

So what will be next in the 1/200? I will be producing the two GPU’s (Houchin C690 and TLD414) of which the Houchin C690 is the most advanced one since I was able to do more tests with it and results were as desired.

Baggage carts will be produced alongside the 1/200 baggage worker figures, this would represent a challenge due the size, but I am confident that it will be possible.

All these new 1/200 releases are planned to be ready before Christmas being the belt loader the first of them with the AST-1 pushback already in the catalog.

Continuing on the 1/144 GSE scale:

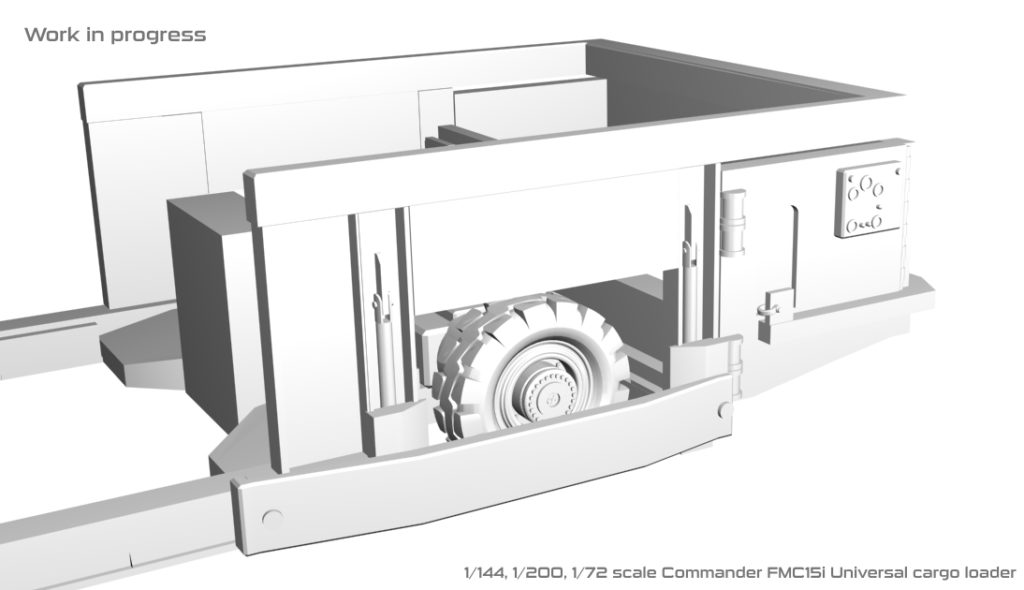

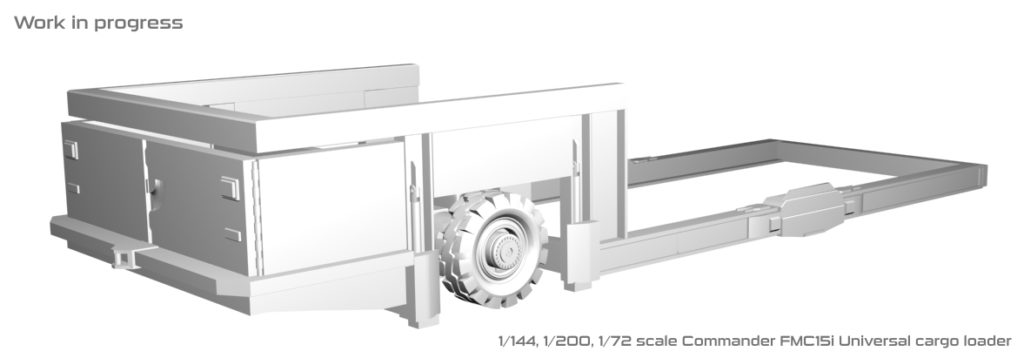

I have been progressing with the Commander FMC15i cargo loader universal, so far the work has been done within the computer and again like the 1/200 models, this cargo loader is scheduled to be released at around the end of the year beginning of next.

Here are a couple of very early renders:

The main difficulty of this model is prepare it so that it can be assembled, it is easy to just join things within the program but then parts will need to be assembled and thus a plan has to be followed to organize how each part will be joined with the other part.

Second, I am considering the possibility to use slide-in micro tubes for the first time in these GSE models, these would be used to simulate the hydraulic columns, what I am not sure about this model in particular is if I will make it movable, meaning that the bridge and platform can move up and down or leave certain heights pre set.

Working on the computer can make things easier to design the way these things would move, but the main issue is if the model will allow this due its possible delicate parts (PE and other detail with wiring that I would like to add), I do not discard this, so I will see how that would work in the next days but it is very possible I will finally make the plafrom and bridge movable.

I am designing this model (like the others) having in mind the 1/72 scale for which I still haven’t been able to progress as much as I wished, the work order on these models is 1/144 first, 1/200 second and 1/72 third.

Designing the models as detailed as possible will (hopefully) ensure that the 1/72 scale will benefit of all the work, because there are physical limits within scales, for example, you cannot make a 10mm nut in real life in 1/200. that would be a 0,05mm nut, it is within tolerances, but nearly invisible, whereas in 1/72 it would be 0,14mm which it could be a bit more visible.

The cargo loader is (at the moment) the only 1/144 GSE model I plan to release before the end of the year beginning of next, it will depend on how much time it takes me to advance and try to equal the 1/200 catalog to the 1/144. There are several other projects that will be made such as catering truck, vans, water cleaners, hydrant, fuel truck and a towbar pushback amongst others.

On regards the 1/144 figures:

I have been trying to improve the drivers of both, the tow tractor JST-25 as well as the belt loader TUG 660.

The main improvement was to have the figure already seated on the seat, which would have a more “push down” effect overall, when you sit on a seat, this pushes down, it is not like siting on a solid rock, so this is somewhat the effect that I wanted.

The copilot is not looking at the back anymore, the trust with the driver has increased so no baggage or cargo would be lost 🙂 overall the positions are more natural. I still need to paint the belt loader drivers for example purposes.

Another matter that I would like to set clear is the figures with helmets; they were done having in mind the Japanese friends, I know they use helmet, so I wanted to have this option as well.

I will still include the seats in the sets, this will be useful in the JST-25 set since you can just leave the driver and the seat empty for the copilot or the belt loader without the driver if the loading operations are ongoing.

These new figures are the ones that will be included in those two GSE sets from now on, because these GSE models were released with the previous figures, I would like to leave these new drivers available separately at the store if you wish to change them.

On regards their size, they represent to be 1,8m tall, or 5 foot 10 inches.

Passengers: There is a set of approximately 15-20 passenger figures on the works, the main season they represent could be autumn – summer and these are specially designed to fit the stairs truck as per the height of the steps. There will be passengers walking upstairs, a little queue and a few passengers walking towards the queue.

This set will be released before Christmas, this is my intention, as you see I have set several new items to be released before Christmas, other figure sets that will follow past Christmas release will be ground workers in different scenarios, pushing back (perfect companion for the push back trucks) parking, and aircraft preparation (cocks and cones).

Airliner stuff:

I have been feeling a little bit frustrated with the 747 cargo project, all due the limitations of the printing technology / materials to produce certain type of parts (thin/flat and long). I will not abandon this project, but I have to think a different approach to create the cargo bay floors.

It would not be an issue if it was just for my own build, because I could assembly everything and glue it on the model, but the main issue is that things have to be made considering two points; the production process and the assembly process.

In any case, I will be working with it and will figure things out. This project will most surely not be ready for Christmas, but it is definitely a 2021 project.

From the frustration of the 747 cargo project I wanted to continue to work inside the airplanes and decided to give a shot to the galleys and cockpits.

Galleys are going to be an important aspect because later GSE models such as the catering will benefit from having an interior open if you are looking for realism.

The figures boarding the airplane will also benefit from having the doors open, so this is something that grown a lot of interest in me, specially because I would like to see dioramas with airplanes in a “loading” or “unloading” stage. The same can be said about cargo holds, which is another work that I would like to do parallel to the galleys, since there will be cargo stuff on the works with the cargo loader.

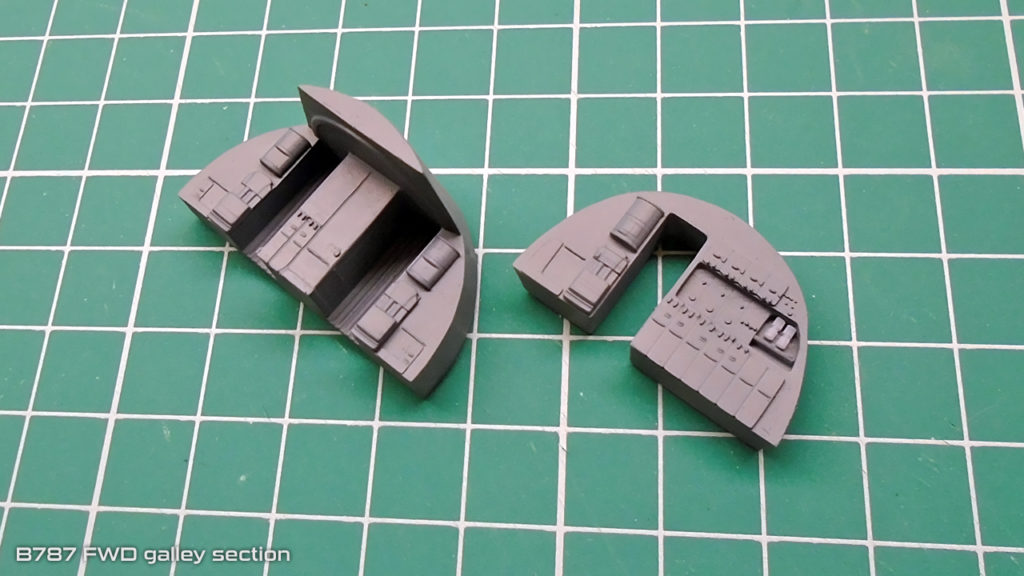

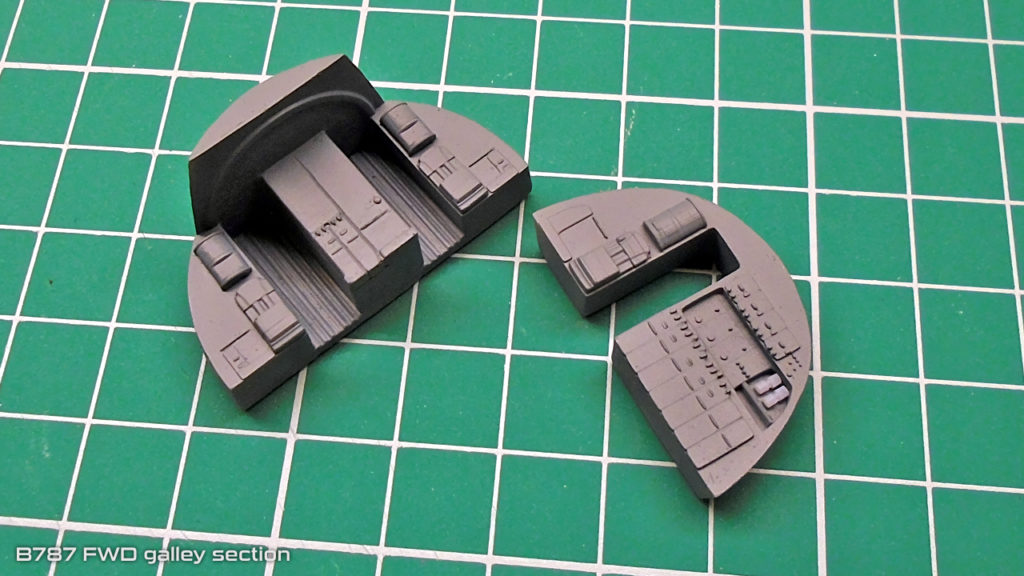

Here is a first attempt for the 787 forward galley section:

As you can see, the module is divided into two, the front panel and the rear panel, or the left panel and the right panel (looking from the boarding side).

Since I will be making galleys for these airliners (A350 is next), I decided to give a try to the cockpit as well due the proximity with the galley, I think it would be ideal to have this as a whole.

The galley projects are at a quite early stage, they will also include the doors and other small detail such as the coffee machines. Note that the seat on the wall closest to the cockpit has the inter phone while the other two seats doesn’t.

The next step to do will be to set the floor and make the frame of the doors, that would be the frame where the door rests in closed position, this frame is overall a bit smaller than the fuselage door frame to allocate the door. Cockpit will also be recreated, however I also look for the cockpit to be a reference point in the assembly process of the whole set into the fuselage.

I will also be making the middle galley and rear galley of this 787-8 (will check the -9 version as well). Galleys are also a project to be scheduled before Christmas.

Sharklets: I still have the A350 sharklets to work with, main issue I have with them is… well, not with them but with the plastic wing which has no airfoil, thus I am thinking that this may be a little bit more than a simple sharklet attachment.

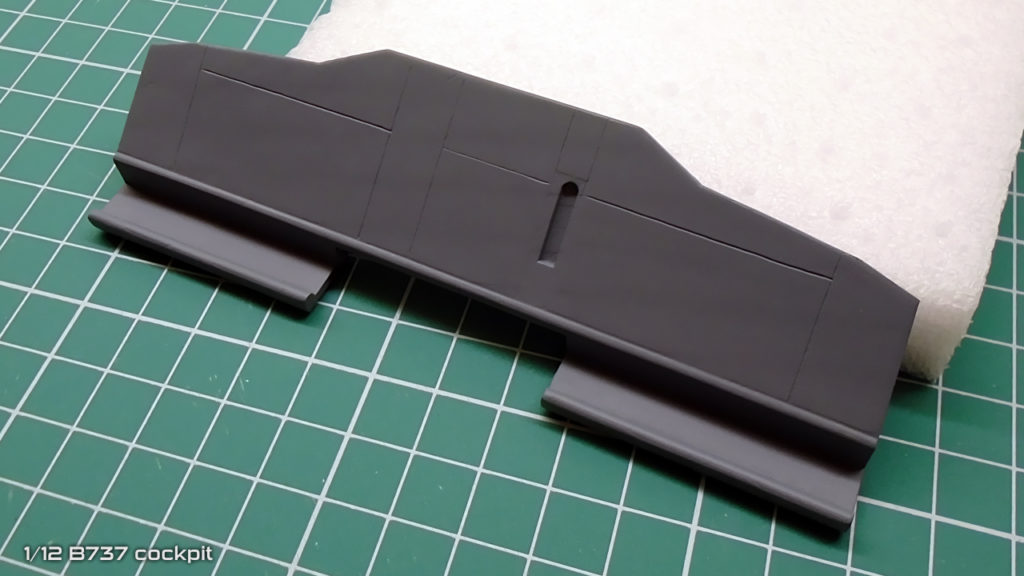

The 1/12 B737 cockpit:

I have been doing lots of tests these days with the main instrument panel of the B737 and unfortunately, it won’t be as easy as to hit “print”. If I want to have the most crisp details, some things will need to be placed “in hand”, I cannot simply print the whole thing, but I need to go section by section and screw by screw in order to make things as crisp and as detailed as possible.

I know that looking at the photo above will seem a step back (or similar situation as before) considering this was already done prior the 3D, but it was important for it to have been done again since everything else will need to fit on top and on the sides.

As you can see, the areas are divided by lines, these areas will be filled in (by the modeler) with the different panels, each panel will have its own parts, such as buttons, knobs, switches, gauges etc so we can say that the lines are basically just for positioning reference. I still need to add a bit of texture on the “footrests”.

Here is an example of several buttons and knobs:

The project will continue on, however this won’t be ready yet this year, when I first started it I knew it was going to be a long project, but I prefer to not to rush things and take the time needed to make it as detailed as possible.

Changes within the store:

There are going to be a couple minor changes at the store, one of them being the handler decals. They are currently now all of them under the same product page and can be chosen from a drop down menu, however, I will create a new category and put each handler decal separately so that it can be easier for the customer to have an overall view of all the decal options, this will also be good for me to have a better stock control and will be better when new decal handlers are added since they will already be visible from the main category page.

Another little change has more to do with the products and shipping, I have purchased a new type of blister which is smaller, it does not affect the weight that much, just a very few grams, but it is easier for me to package. The smaller items such as the figures, sharklets, LD3 containers will be shipped inside a new mini blister, this will hopefully bring even more protection and a better presentation to the overall product.

Livery decals:

There is not much to say about the livery decals except that I am still awaiting for the printing company response. My guess is that they are currently very busy after the summer holidays and will probably need to catch up with emails and works for other clients they have.

It is my intention to continue with this, try to contact them again and hopefully arrive to a conclusion.

Livery decals will be back, my idea would be that they could do so before Christmas, but it will all depend on other main factors such as the printing and the modifications required for the artworks.

It has been a quite big entry, probably the longest, but my “holidays” have been this, testing things, working on other items and continue shipping orders.

Now work continues and I will be producing units again, so I expect to restock these models in the next few weeks.

Unfortunately I haven’t had a lot of time to build my “one per year” airliner, but I will be working with it during the weekends.

Wish you are all safe, the situation with the Covid is very unstable still, but I am sure that with time things will get better.

Best wishes,

Guillem