Hello everyone,

About to be at Christmas in a week, I wanted to share with you how are things going with the B787.

I do have good news and I sadly also have “bad” news.

I would like to do a bit of explanation about what it is to work with such sensitive materials no matter which time of the year.

I am at the moment doing tests (yes, still) with the transparent resin, however, the good side of it is that I have learned a lot more about this material and I am in the middle of a decisive test.

Temperatures have changed by about 15ºc since my last test with the transparent resin. So what happened when I went on to make the transparent parts was to see that I was no longer able to remove the bubbles that are always an issue in such type of resins. The problem was that the resin changed its viscosity.

I did however, managed to solve this by warming the resin and then, as always, using my pressure pot to get rid of those bubbles.

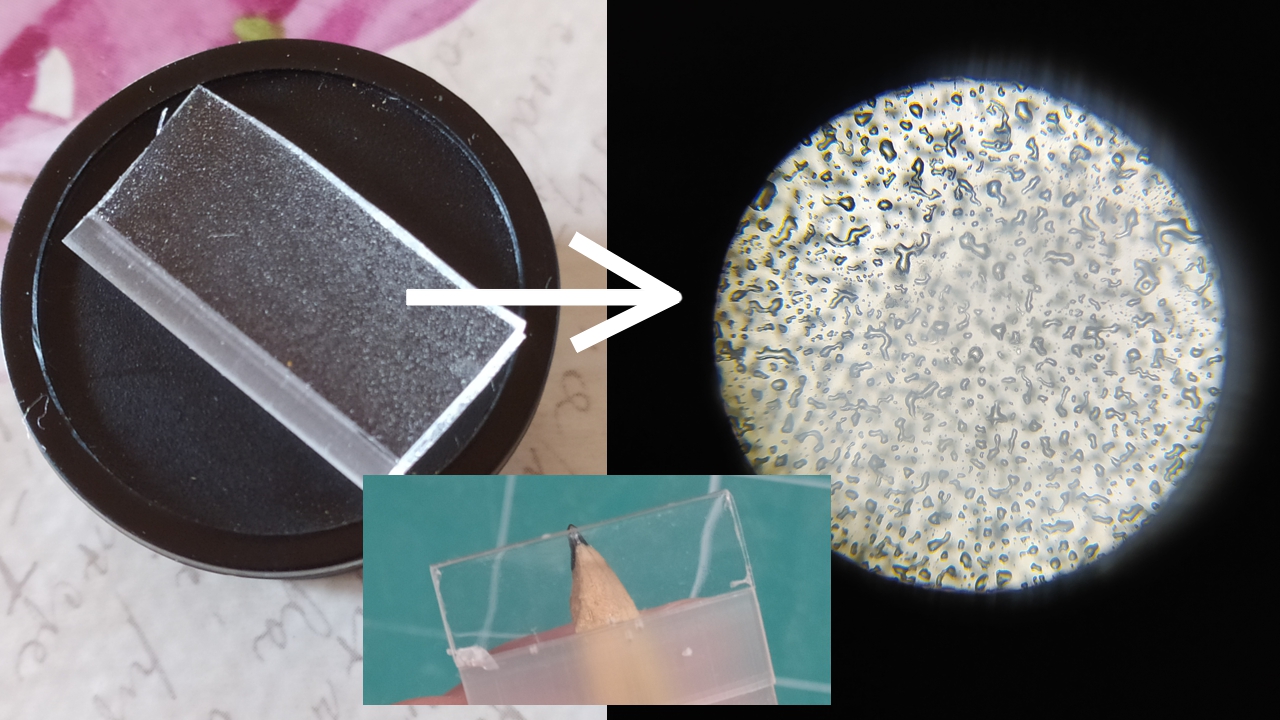

Problems solved, right? No… A wrong preparation of the part (for a test) of which I made the mold of a long time ago has mislead me for a bit, you see, to the naked eye, there was no issue with the surface, it was smooth and shiny, but the results kept showing me some sort of bubbles, which I later found out they weren’t, there were very tiny pores that become obvious when using such type of transparent materials and for a while, I thought the problem was in the resin itself, so another problem solved, the resin was working but the part used for the mold wasn’t properly prepared.

I don’t want to get into a lot of details, but the theory and practice is that, if you want a fully transparent part, the master part or area must be smooth and shiny, silicone used to make the mold will actually capture that surface, and the result will be a full clear area instead of it being translucent, that is, smooth/shiny= transparency, pores= translucency.

Not only I discovered the viscosity and base part issues, but also discovered that not all silicones are ideal to do this kind of job.

Being tired of these problems, I decided to take the microscope and see what were those deffects. I understood then, that those were not micro bubbles, but actually the resin not flowing properly inside the mold, as when the paint doesn’t adhere well to the surface, so then I realized, also by the touch of it, that the silicone had some bit of grease, thus making it not adequate for this task.

Where do we stand now?

A test with multiple surfaces is being done, this time with a different type of silicone. I know it should work because it did, as you can see from the microscope photo, image below, with a silicone I used (for which there is no stock at the moment). Once I can see the results in a few days (materials take their time to dry), I will be able to apply this to the B787 windshield and doors.

For this, and this very only reason, I won’t be able to release this for Christmas yet, since everything else is done, even the main printed parts are done, the transparent parts will take me a bit more, not to mention the resin takes a few days to fully cure due the nature of the parts, that is, small and thin.

If the results from the test come out fine, there is a very high chance I will be finally releasing those items at the beginning of 2024, what is obvious is that I can’t release something that isn’t finished, but believe me when I say I am putting my biggest effort on this project to the point of running out of hours a day within a healthy limit.

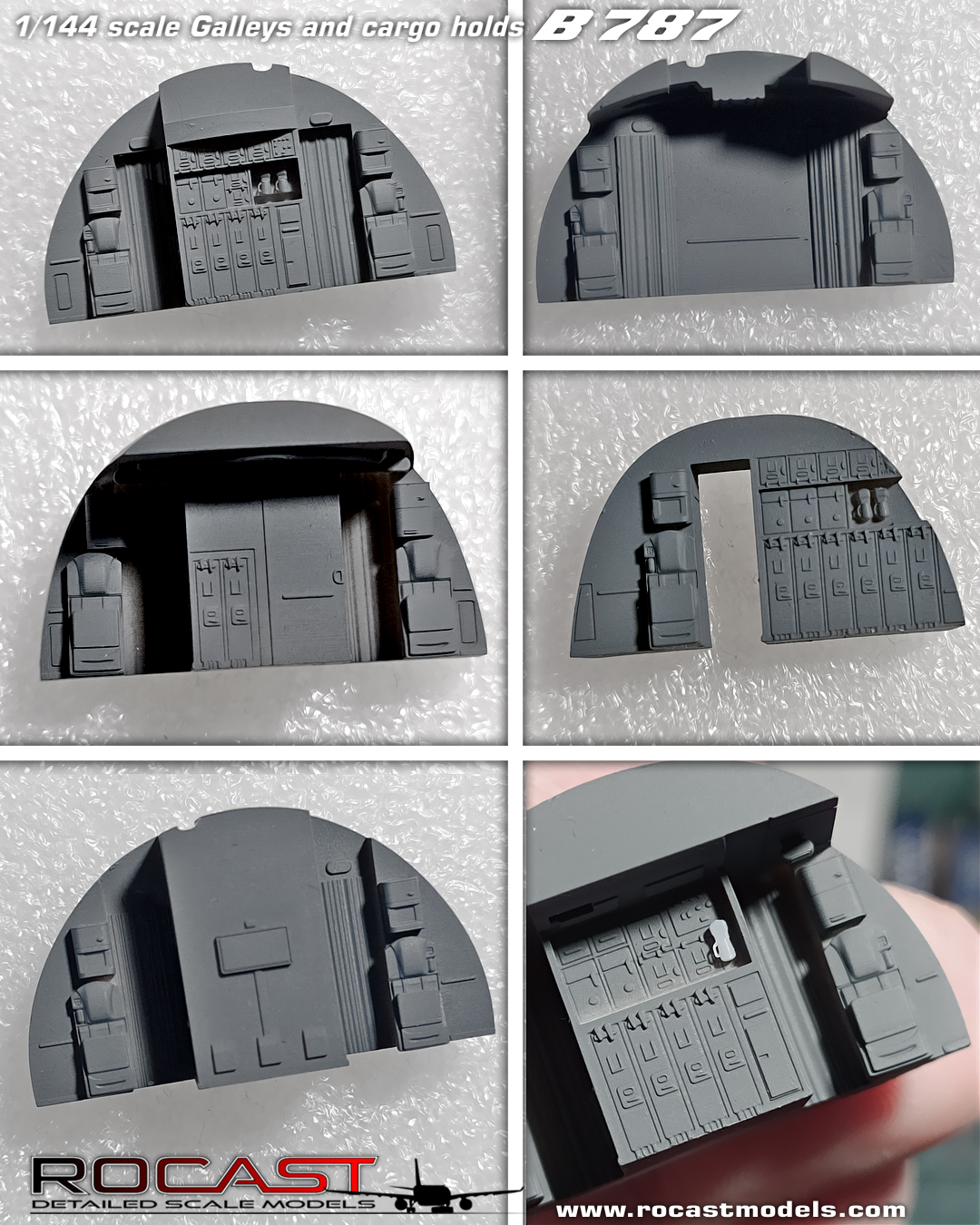

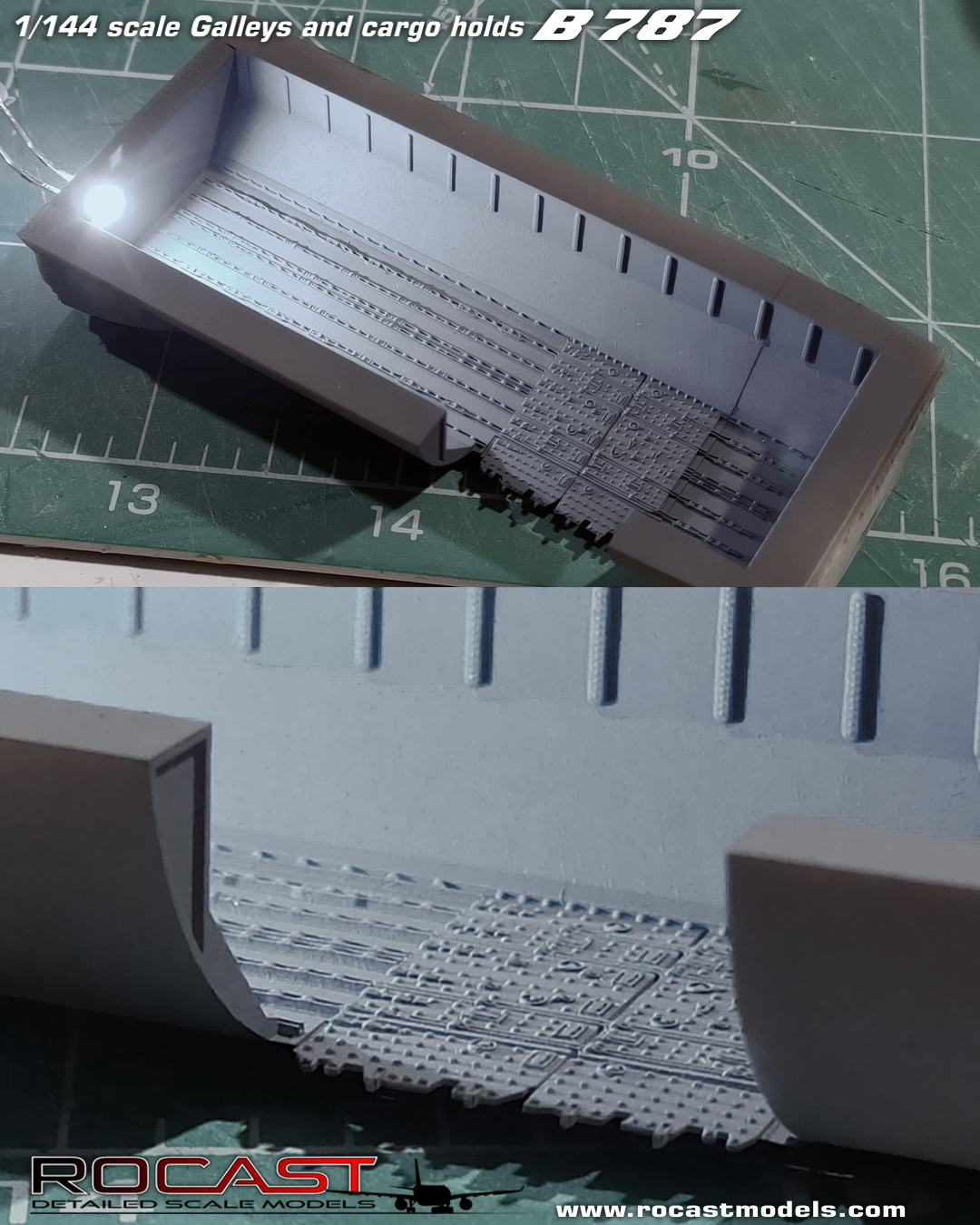

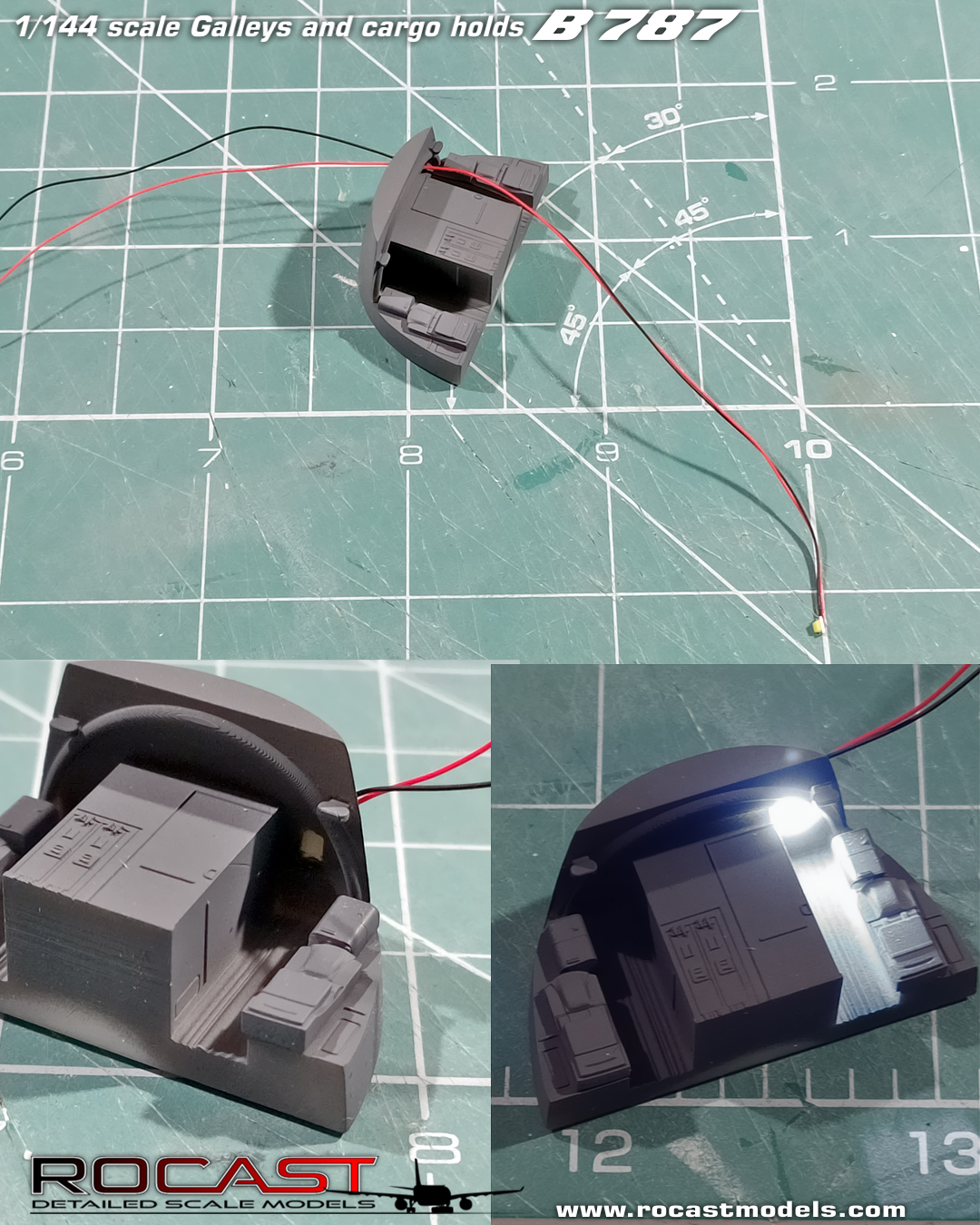

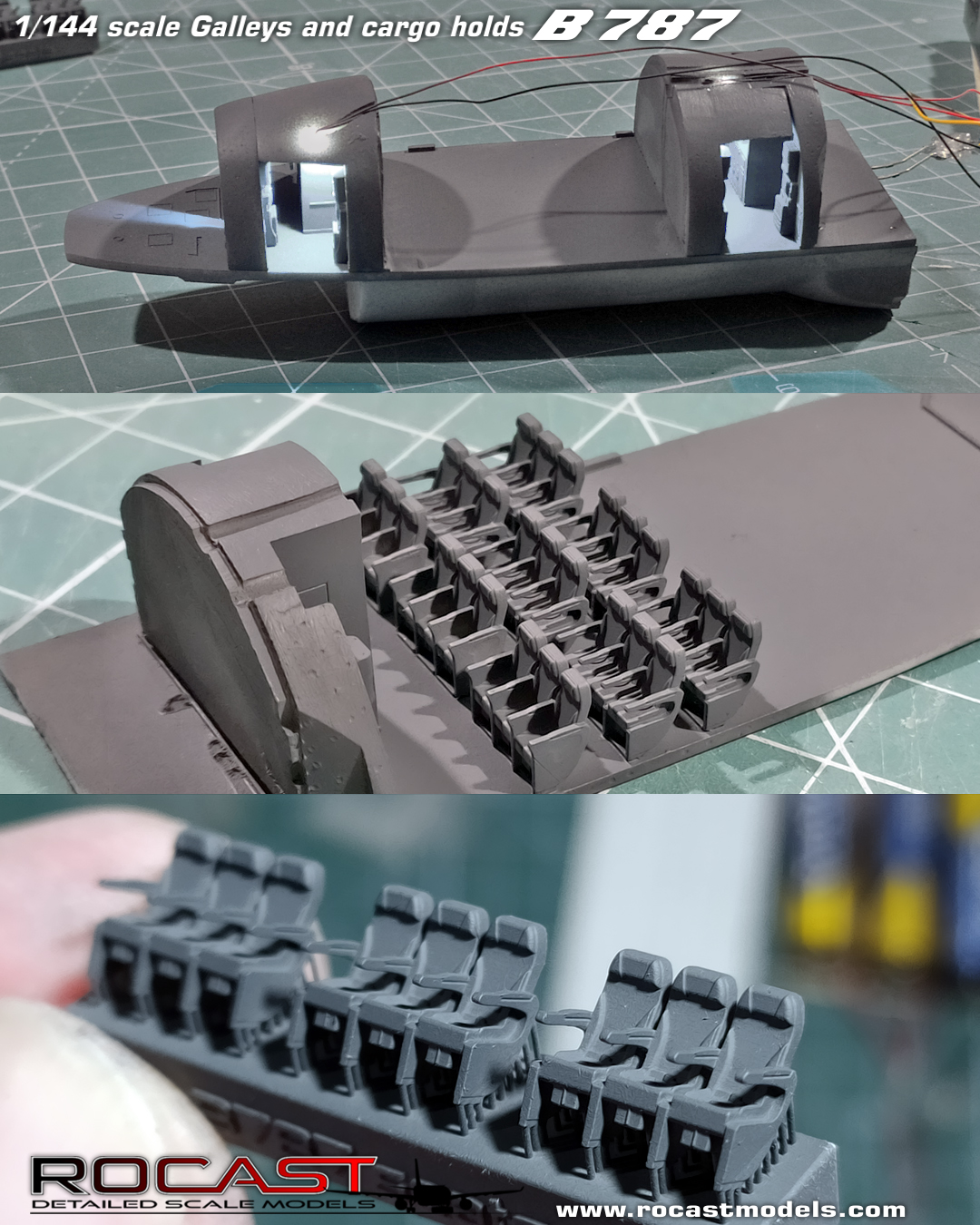

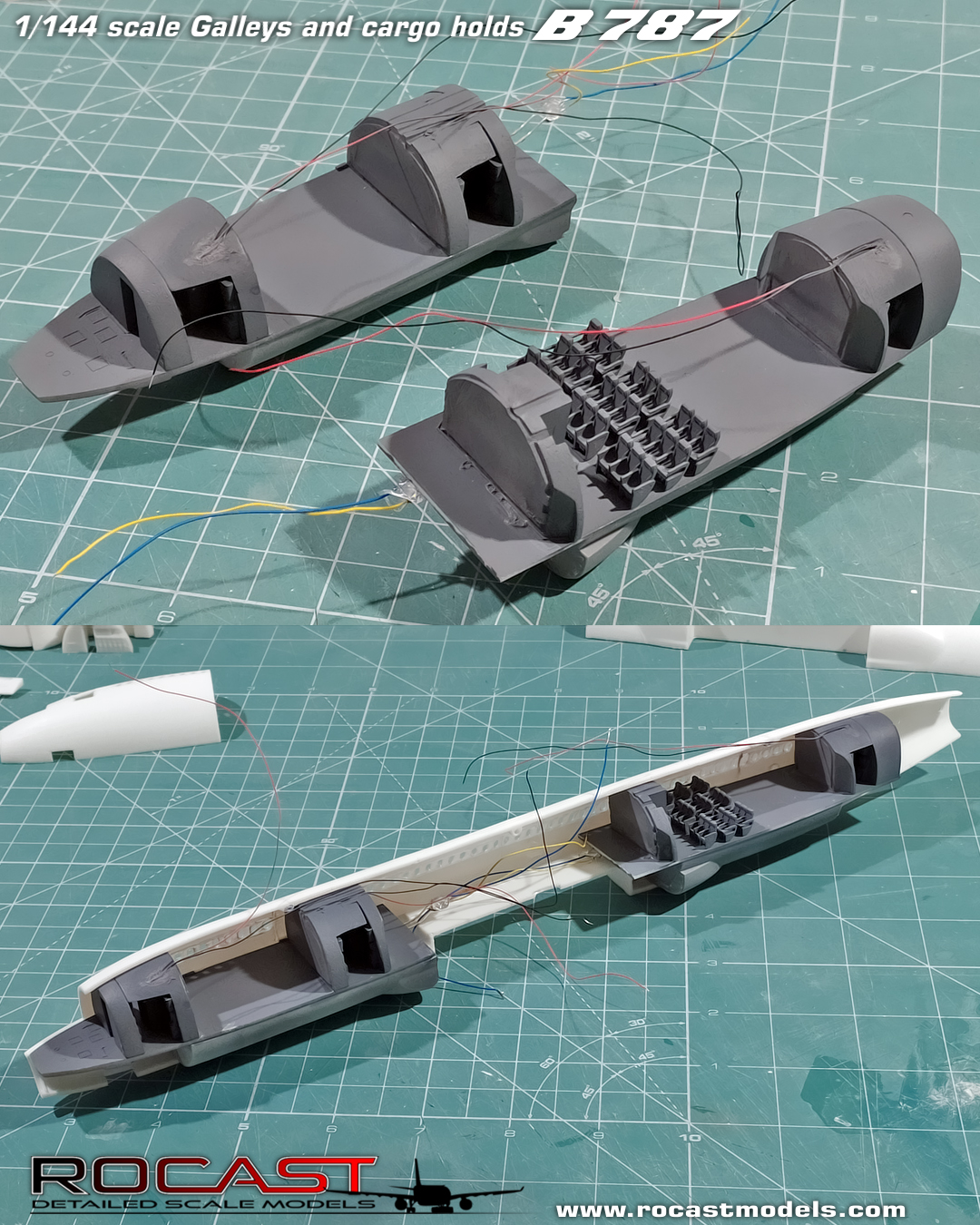

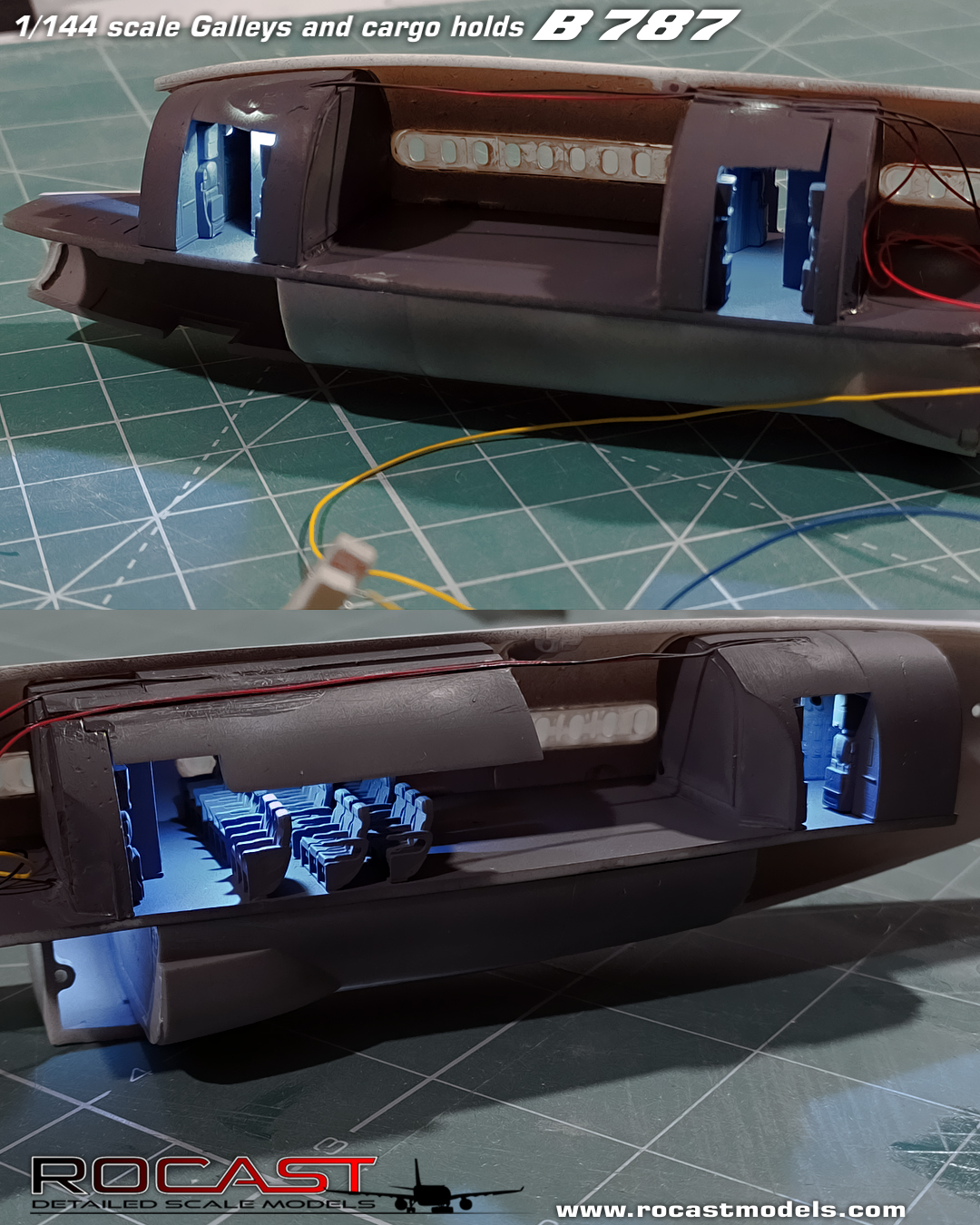

I do use the weekends to work on my example “primed” model, so here are some photos of it:

This is all for now, work continues, obviously my main focus is in trying to solve the issues to make the transparent parts, I wish you could see how difficult things can be sometimes, materials are directly affected by climatology, and what may work on summer may not work on winter and vice versa, so there is still some road ahead, but this project is a reality and it will be completed.

From here I apologize for the bit of delay, it really catch me off guard seing how the transparent resin changed, so I had to learn, but I am positive the results will also come out positive.

Before I leave this post, I wanted to share a new gallery that I’ve just created from a fellow modeler from the US, I was contacted by Ben and I was incredibly surprised by his skills, I know how small those things are and the paintjob of those little details is superb, I hope you guys will enjoy it as much as I do:

Ben’s gallery:

Take good care everyone, I will be back with more news soon.

Best wishes,

Guillem