Dear all,

In this entry I will be writing about something that I felt I needed to mention.

As you probably know, restocking is something that always takes me a very long time, it is often the case that a model becomes out of stock and it takes weeks for me to get it back in stock, this is not because I am not working on it, but for the reason I will explain below.

I have been taking some considerations and I reached a point where I could not be spending hours and hours cutting hundreds and hundreds of tiny parts cause I felt I was in a way doing something that a modeler should be doing instead and that no kit or manufacturer ever does, which is provide all the parts cut off their base. Can you imagine Revell or Zvezda or any other plastic kit manufacturer for that matter, cutting all the parts from their plastic burrs and baggaging them pre sanded and ready? It would take a lot of effort that I can actually invest in other matters such as Photo etching which I finally was able to fix.

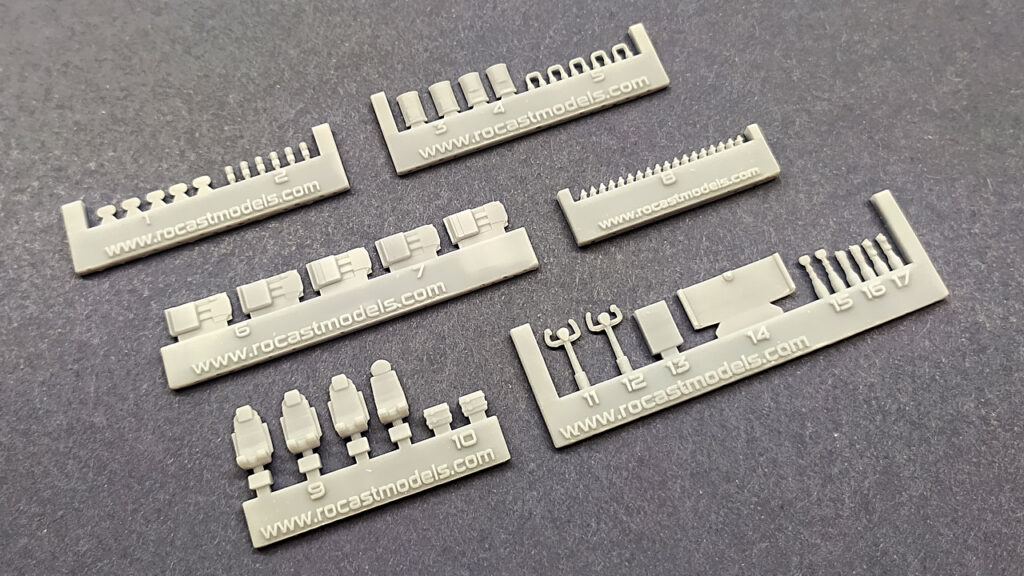

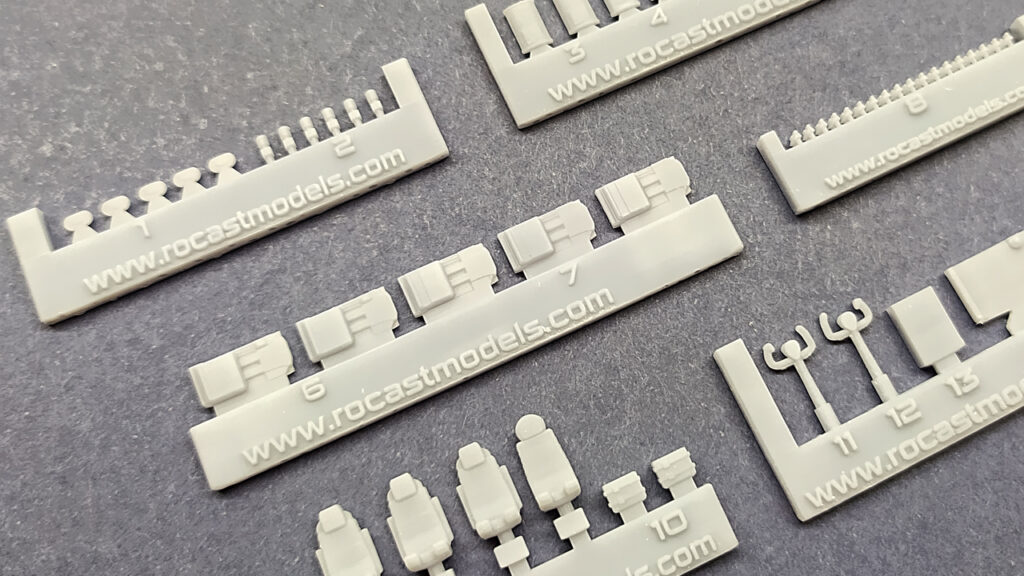

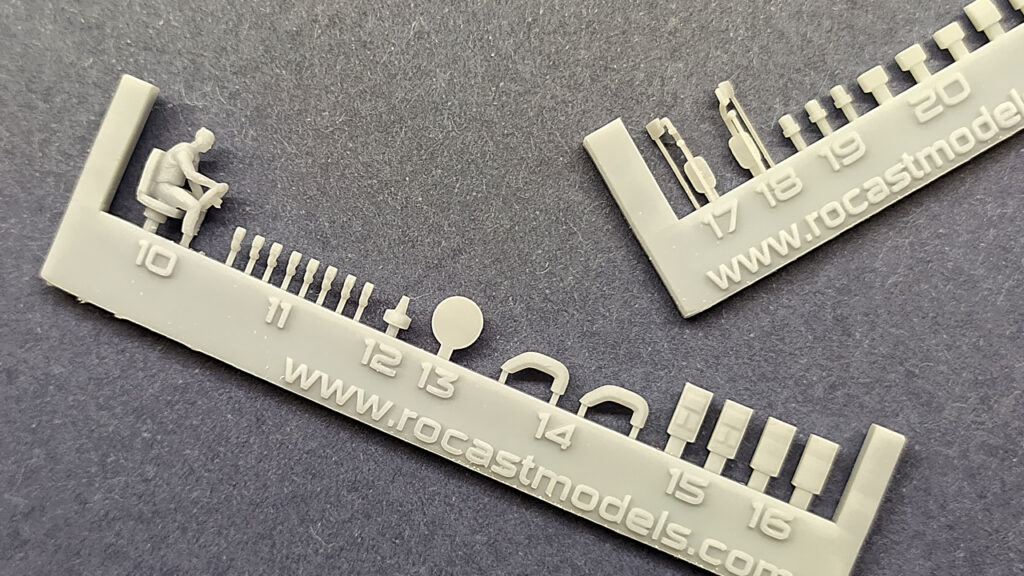

I have done some tests with the cockpit and galley parts as you can see from these photos:

Click on the image to show closeup details

This is not much different than what I used to do long ago, and in my opinion it presents more positive points than cons.

- Customer won’t have to be worried to open a bag and have lots of tiny pieces lying around to pick a specific one.

- Now, thanks to the base, I can add numbers below each part to make things easier to understand in the instructions.

- Instructions will have a specific step that will show where the cut to remove the part off the base needs to be done at (even though this is quite self explantory).

- Having the parts in their bases makes it for a more tidy presentation, modeler can cut the part that need to be used whilst leaving the others on the base.

- Level of detail is still the same as the previous parts.

- For some specific parts, the painting may be done easier as they are already on a base.

- I still include spares knowing that some parts may be quite small.

The only con that comes to mind is the extra need of material, which in my opinion, is well worth it.

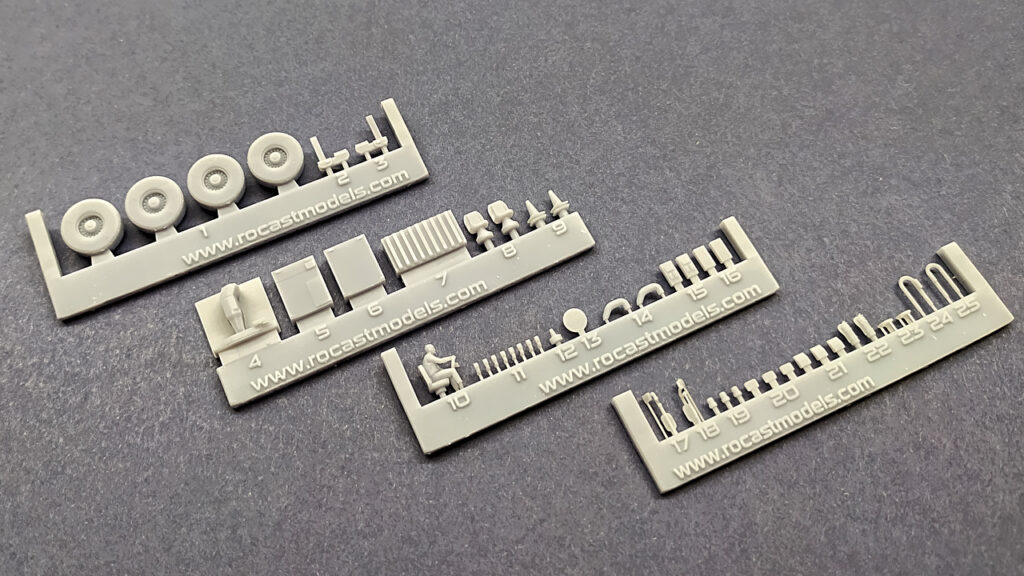

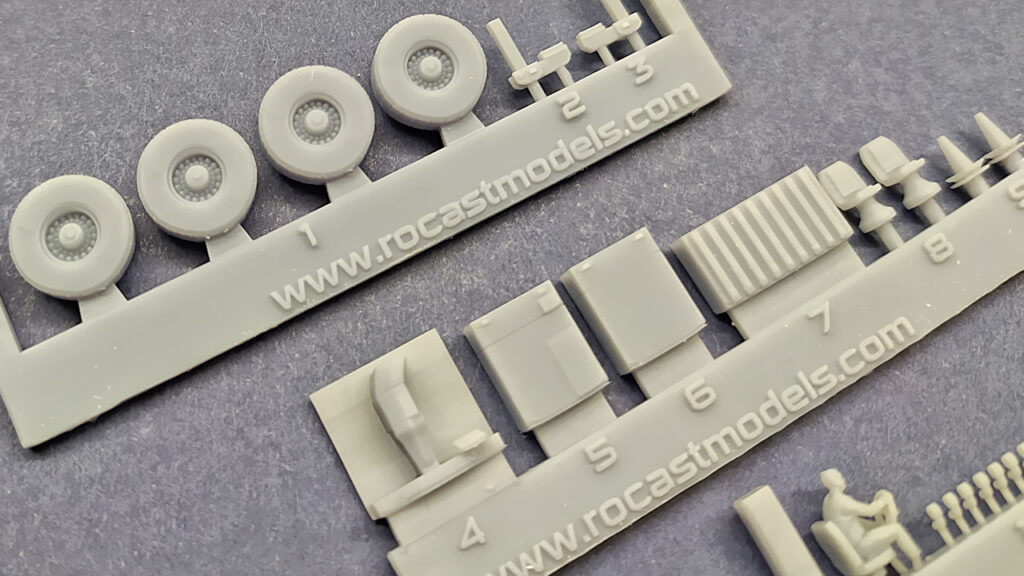

Here is another example with most of the AST-1 Towbarless pushback truck parts:

Click on the image to show closeup details

In my previous entry I was mentionig that I was not sure to do this with the GSE models, but seeing the results, I will certainly be doing these modifications to the following models:

- Towbarless pushback AST-1F 600

- Belt Loader TUG660

- Ground Power Unit Houchin C690

- Ground Power Unit TLD414

- Tow tractor TLD JST-25

- Stairs truck TLD ABS1740

- Cargo loader Commander FMC15i (and all its double scissor extra parts).

Some parts will still be provided as they were before, such as the cabins, main bodies (in the case of Belt loader, JST-25, cargo loader, stairs truck).

All in all, the best advantage of this is for me to prepare these more readily and have them available more often, have time to work on other areas such as each PE, as well as have more time to work on current projects.

This process will take me some time but I am already completing the first batch of B787 galleys (all sections). So my objective is to update all those parts and have the items (all of them) ready simultaneously and therefore start this cycle with everything in stock.

I hope that you guys agree with me that this is a more plausible way to provide those parts, to cut off the base those parts, a small cut is all it’s needed, but this saves me many hours that I can use to produce other parts of the kit and also to have these items in stock more often, which is important for me to keep this thing moving.

On a last note, the A320/A321 (and neos) as well as the A350-900/A350-1000 silk screen decals have arrived home and will say only one thing; they look gorgeous.

I won’t be giving more info until I have everything ready (laser parts as well as the new instructions which will be presented as an A4 sheet, no bends).

Work continues to adjust all those parts but work also continues with the ongoing projects.

Wish you all are safe and sound, please take care,

Guillem